Plastic classification, solid waste treatment and innovative application of plastic granulators

With the continuous increase in the global use of plastics, the treatment and recycling of plastic solid waste has become an important topic of environmental protection and resource recycling. The development of plastic classification and recycling technology, especially the application of plastic granulators, is promoting the sustainable development of the plastic recycling industry.

Classification and characteristics of plastics

Plastics are a kind of high molecular polymer. According to their chemical structure and use, they can be divided into the following categories:

General plastics: including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS) and acrylonitrile-butadiene-styrene copolymer (ABS). These plastics have a wide range of applications, such as packaging materials, building materials and daily necessities.

Engineering plastics:such as polyamide (PA), polycarbonate (PC), etc., have high mechanical properties and temperature resistance, and are often used in automotive, electronics and machinery manufacturing.

Special plastics:such as polytetrafluoroethylene (PTFE), etc., have special properties, such as high temperature resistance and corrosion resistance, and are used in high-end industrial fields.

Current status and challenges of plastic solid waste

Plastic solid waste, especially waste plastic film, plastic packaging and disposable plastic products, has become a global environmental problem. These wastes not only occupy a large amount of land, but also cause serious pollution to soil, water and marine ecosystems. Traditional treatment methods, such as landfill and incineration, not only waste resources, but also produce harmful gases and greenhouse gas emissions.

Innovative application of plastic granulator

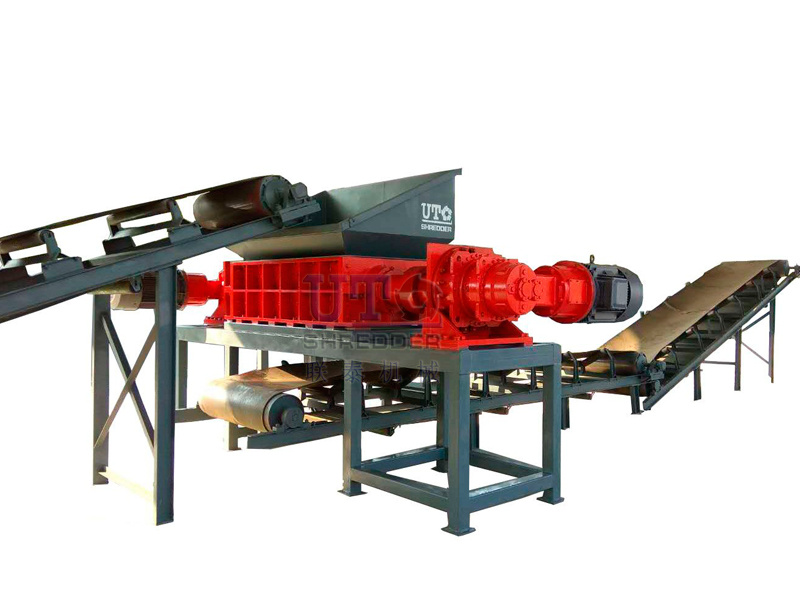

Plastic granulator is a key equipment for plastic recycling and reprocessing. Its function is to process waste plastic into granules for subsequent reuse. In recent years, the technology of plastic granulators has been continuously innovated to improve production efficiency, reduce energy consumption and improve product quality.

Modern plastic granulators use an automated control system to achieve full process automation from raw material crushing, cleaning to granulation. These devices are also equipped with a high-pressure friction uninterrupted heating system, which automatically heats the production and avoids continuous heating, thereby saving electricity and energy.

Economic and environmental benefits

The innovation of plastic granulators not only improves production efficiency, but also brings significant economic benefits to enterprises. Through efficient screening and recycling technology, enterprises can reduce material loss and energy consumption and reduce production costs. In addition, plastic recycling reduces the demand for virgin plastics, reduces environmental pollution, and promotes sustainable development.

Conclusion

The classification and recycling of plastics are key links in achieving sustainable development. With the continuous innovation of plastic granulator technology, the plastic recycling industry is moving towards high efficiency, energy saving and environmental protection. In the future, with the emergence of more technological innovations, plastic recycling will make greater contributions to environmental protection and resource recycling.

CN

CN

EN

EN

TEL:+86-533-3588750

TEL:+86-533-3588750 FAX:+86-533-3588750

FAX:+86-533-3588750 MOBILE:+86-18653354363

MOBILE:+86-18653354363 E-MAIL:info@zbutm.com

E-MAIL:info@zbutm.com ADDRESS:No.145 Zhengtong Road,

ADDRESS:No.145 Zhengtong Road,