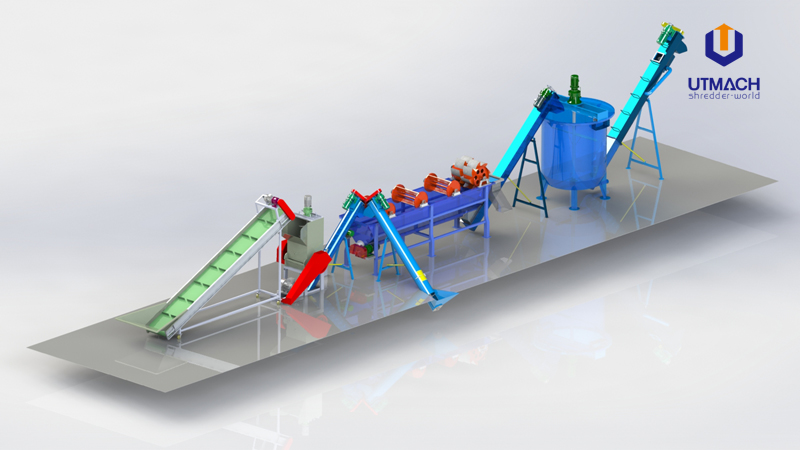

PET Bottle Granulating & Recycling Line

PET bottle crushing and recycling line is suitable for crushing and cleaning waste PET bottles (including labels and caps) and separating labels to produce pure, dry and uniform size PET plastic flakes. Waste PET bottles exhibit diverse product specifications and material characteristics due to the complex recycling sources, for which we specially customize a series of recycling production solutions to meet the different production needs of our customers.

This line series is widely used for recycling PET bottles for various purposes, including waste mineral water and beverage bottles, detergent and daily chemical product containers, snack containers, medicine bottles, and industrial PET bottles and tubes, etc.

Suggested Recyling Line machines for reference:

1. Bale opener : break up the extruded PET bottles

2. Disc sorting machine : remove stones, heavy objects and dislodged bottle caps

3. Manual sorting platform (optional) : manual sorting according to PET bottle type and color

4. Metal detection and separation equipment : detect and separate metal contaminants left in PET bottles

5. Pre-washing machine : cleaning part of the contaminants, such as residual beverage liquid

6. Shredder ① : add water to crush, so that the size of the bottle flakes reduce and get cleaned

7. Spiral washing machine ① : cleaning and transferring materials

8. Shredder ② : add water to crush, so that the bottle size further reduced, and continue to get cleaned

9. Spiral cleaning machine ② : continue to clean and transfer of materials

10. Centrifugal dehydrator ① : cleaning and drying bottle pieces

11. Debarring system ① : remove part of the label and residual contaminants

12. High-temperature cooking pot : high-temperature cleaning to remove glue and grease

13. Rinsing and sedimentation tank : remove floating labels and caps, further cleaning of precipitated bottles and

flakes

14. Centrifugal dehydrator ② : dehydrating the bottle flakes

15. Label removal system ② : remove residual labels and contaminants

16. Fully automatic bagging system : to fill the finished product into storage bags or packaging bags

We provide customized machines, if you have any questions, please feel free to contact our sales.

CN

CN

EN

EN

TEL:+86-533-3588750

TEL:+86-533-3588750 FAX:+86-533-3588750

FAX:+86-533-3588750 MOBILE:+86-18653354363

MOBILE:+86-18653354363 E-MAIL:info@zbutm.com

E-MAIL:info@zbutm.com ADDRESS:No.145 Zhengtong Road,

ADDRESS:No.145 Zhengtong Road,