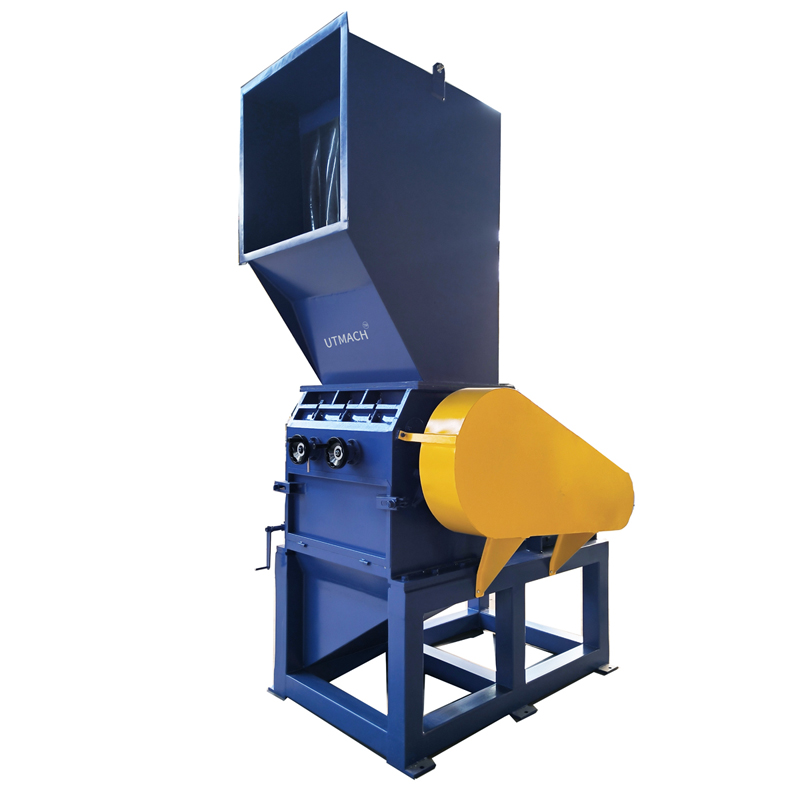

Heavy Duty Granulator

The heavy-duty granulator is a robust industrial machine designed to break down large materials into smaller granules or particles. These machines are typically used in various industries for size reduction, recycling, and processing of materials such as plastics, rubber, wood, metals, and more. Here are some key characteristics and features of a heavy-duty granulator

Advantages:

Robust Construction: Heavy-duty granulators are built with sturdy materials and components to withstand the rigors of continuous operation in industrial environments. They are often constructed with heavy-duty steel frames and reinforced cutting chambers.

High Cutting Power: These granulators are equipped with powerful motors and cutting mechanisms capable of efficiently shredding and granulating large volumes of materials. They employ sharp blades or cutting discs to cut through the materials effectively.

Versatile Applications: Heavy-duty granulators can handle a wide range of materials, including plastics (such as PET, PVC, HDPE), rubber, wood, paper, cardboard, textiles, metals (such as aluminum, copper), and more. They are used for recycling scrap materials, processing industrial waste, and preparing materials for further processing or recycling.

Variable Cutting Configurations: Many heavy-duty granulators offer adjustable cutting configurations, allowing operators to customize the size and shape of the granules or particles produced. This flexibility enables them to meet specific processing requirements and produce uniform granules for various applications.

Safety Features: Safety is a priority in industrial machinery, and heavy-duty granulators are equipped with various safety features to protect operators and prevent accidents. These may include safety guards, emergency stop buttons, automatic overload protection, and safety interlocks.

Ease of Maintenance: While heavy-duty granulators are designed for heavy-duty operation, they also require regular maintenance to ensure optimal performance and longevity. They are typically designed with easy access to internal components for maintenance and cleaning purposes.

Integration with Other Equipment: Heavy-duty granulators are often part of larger processing systems and can be integrated with other equipment such as conveyors, shredders, separators, and extruders to create comprehensive recycling or processing lines.

Overall, our heavy-duty granulators are essential machines in industries where size reduction, recycling, and material processing are key operations. They offer high performance, versatility, and durability to meet the demanding requirements of industrial applications.

Specification:

Item | Model | Screen Size (mm) | Power (kw) |

Heavy Duty Granulator | G30 | 12 | 30 |

G35 | 12 | 37 | |

G40 | 15 | 45 | |

G50 | 20 | 55 | |

G60 | 20 | 75 | |

G70 | 20 | 90 |

Note:

1. The voltage and motor power about the power supply can be selected by the customer’s specific requirements.

2. The granulator capacity can be influenced by the material composition and output size.

3. We provided customized machines. The above specifications are only for reference and subject to change without prior notice, please confirm with our sales representative when making order.