The photovoltaic panel recycling line is a specialized, environmentally friendly processing facility designed for waste solar panels, photovoltaic glass, silicon wafers, and aluminum frame components. With the rapid development of the photovoltaic industry, a large number of retired photovoltaic panels require scientific and safe recycling. The system developed by UTMACH automatically crushes, removes iron, delaminates, sorts, and finely separates photovoltaic panels, maximizing the recovery of reusable resources.

This equipment is widely used in retired photovoltaic power plant component processing centers, renewable resource recycling companies, and environmental protection equipment manufacturers.

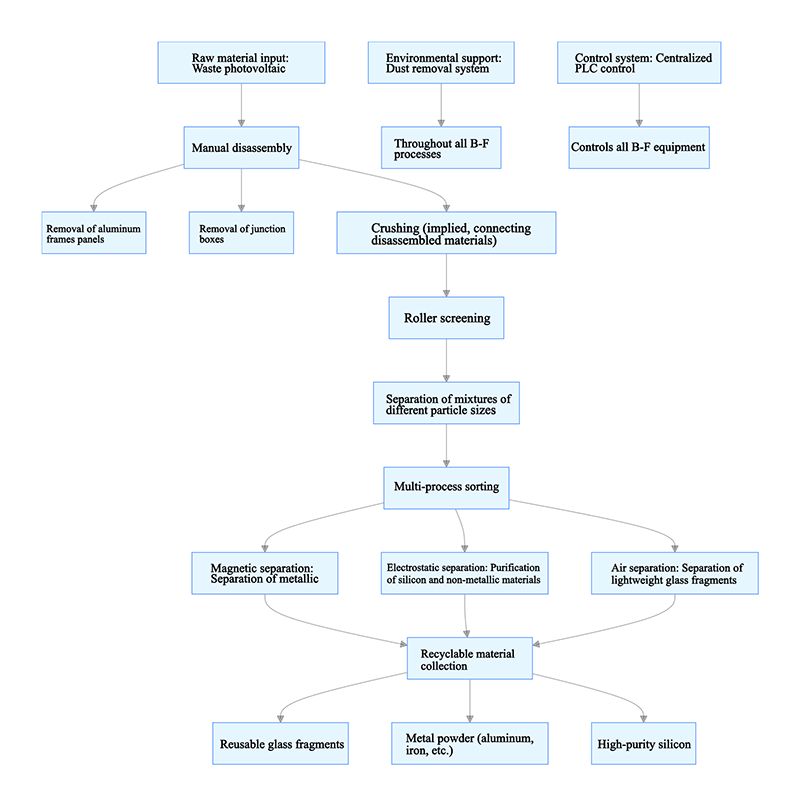

Workflow

Manual Disassembly: Removes aluminum frames and junction boxes.

Screening: Roller screening crushes and separates mixtures of varying particle sizes.

Sorting: Separates glass, metals, and non-metals through magnetic, electrostatic, and air separation methods.

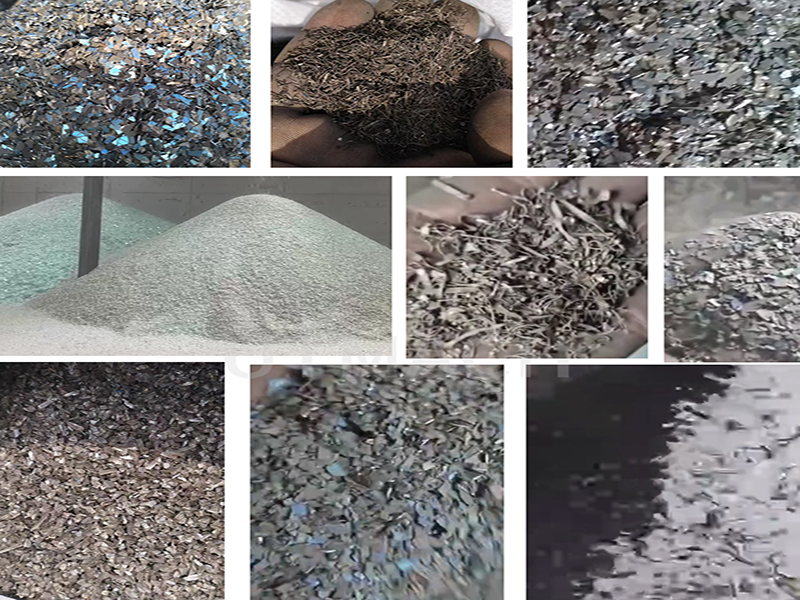

Recyclables Collection: Recovers reusable glass fragments, metal powder, and silicon materials.

Technical Features

High Recovery Rate: Recovers over 90% of glass, silicon wafers, metals, and other materials.

Low Investment: Utilizes highly efficient and energy-saving sorting equipment.

Modular design: Flexible configuration based on production capacity requirements.

Environmentally friendly and pollution-free: Equipped with a dust removal system, it meets environmental standards.

Automated control: Centralized PLC control enables intelligent operation.

Applications

Waste photovoltaic module recycling.

Recycling of retired photovoltaic power plant equipment.

Comprehensive recycling of waste electronic materials.

Environmental protection industry recycling projects.

Environmental and economic benefits

Reducing photovoltaic waste landfills and protecting land resources.

Recovering high-purity silicon and metal materials increases economic returns.

Achieving a circular economy model of "green recycling, reuse, and low-carbon development."