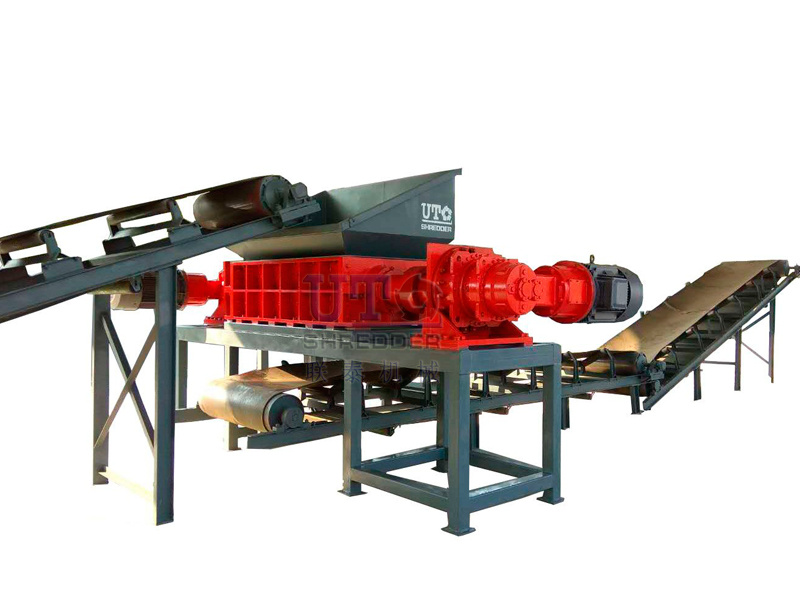

Necessary operation matters for use of shredder

When the dual axis shredder starts to work, the tool begins to bear the wear caused by friction. Therefore, as long as the single axis shredder or the multi axis shredder is used, it will be impacted and polished by materials at the same time. Over a long period of time, the tool will be worn, and the appearance of the tool and the edges and corners on both sides will gradually become circular arcs.

Therefore, when the force of the biaxial shredder is transferred and the tool wear effect changes, it indicates that the tool life is about to end. When the discharge cannot meet the downstream requirements of the production line, the tool has failed and needs to be replaced in time for normal production.

1. Attention for disassembly

When disassembling and replacing, it is necessary to protect the alloy head. The damage of the alloy head will cause serious impact, resulting in more necessary expenses. Attention shall be paid to avoid injury caused by sharp edges during disassembly and assembly to ensure safe disassembly and assembly.

2. Inspection is indispensable

The first thing you need to do to maintain the shredder blade is to check it regularly. The regular inspection is mainly to check the engagement of the blade. If the engagement does not match, it must be adjusted to avoid damage to the blade. At the same time, it should be noted that the area around the blade must be kept clean before installation to avoid any sundries.

3. Idling is indispensable

For blade inspection, it must be noted that the blade must be idle for 30 seconds after installation and inspection. If there is no abnormal condition after idling for 30 seconds, it can be started normally for cutting. If there is abnormal noise during idling, the machine must be shut down for inspection.

CN

CN

EN

EN

TEL:+86-533-3588750

TEL:+86-533-3588750 FAX:+86-533-3588750

FAX:+86-533-3588750 MOBILE:+86-18653354363

MOBILE:+86-18653354363 E-MAIL:info@zbutm.com

E-MAIL:info@zbutm.com ADDRESS:No.145 Zhengtong Road,

ADDRESS:No.145 Zhengtong Road,