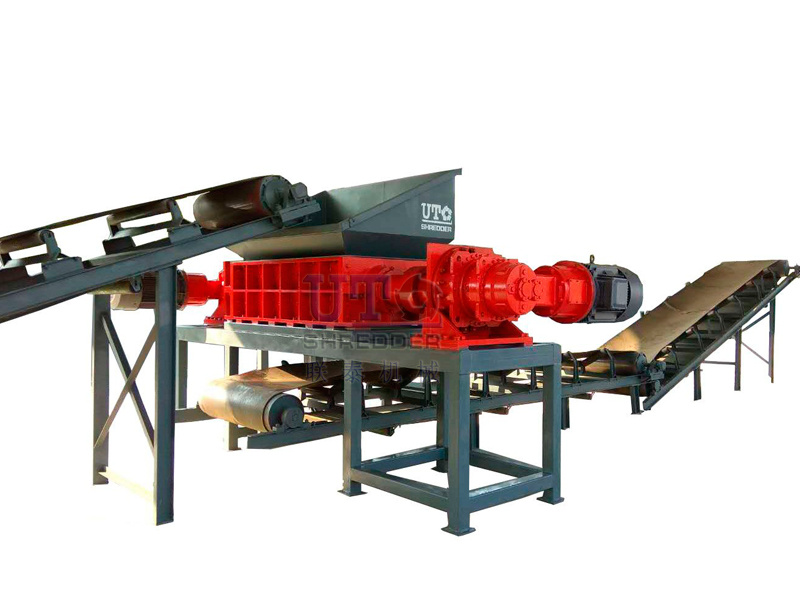

Maintenance of shredders

Precautions for safe operation of shredders:

5.1 Start-up:

Before starting the shredder, make sure that the reducer has been filled with reducer oil and the bearings have been filled with lubricating oil.

Before starting the shredder, first check whether the shredder knife box is free of foreign debris, whether the knife, spacer, and fixed knife are damaged, and start the machine after ensuring that there are no abnormal conditions.

Check whether the control switches of the electric control box are in the open state, and ensure that there are no safety hazards in the electric control box before starting the machine.

5.2 Loading:

When loading, try to keep it evenly hooked to avoid frequent activation of overload protection causing damage to electrical components and motors. Small shredders should try not to contain large pieces of metal debris in the shredded materials to avoid damaging the knives during the operation of the shredder. Larger shredders can generally crush metal objects 5-8MIM thick.

5.3 Process control:

When excessive vibration or abnormal noise occurs during the crushing process, the machine should be stopped for inspection to see if any hard objects have fallen into the knife box, causing damage and deformation of the knife and spacer. After eliminating the problem, check the operating conditions of the reducer and motor step by step.

During the operation of the shredder, the inside of the knife box, the electric control box, and the machine body shall not be manually cleaned.

Maintenance precautions for shredders:

①When inspecting, repairing, and maintaining the shredder, the power supply must be cut off and a warning sign must be hung.

②Only after the shredder is completely stopped can the shredder be inspected, maintained, and replaced.

③Visually inspect the blade every week to see if there is any damage or tooth collapse.

④Measure the radius and thickness of the tool to arrange the appropriate time for tool repair.

⑤Regularly repair the blade. The frequency of repair varies depending on the type of garbage being crushed. Once the blade is found to be damaged, it must be repaired immediately.

⑥When the repair does not work, replace the blade.

Daily tips:

●Before leaving get off work, the uncrushed residual material in the knife box should be crushed before stopping the machine.

● Turn off the power switch, clean up the materials scattered around the crusher, and check whether there are any loose screws at the joint between the motor and the reducer.

Alarm bells:

There is a round oil level mirror on the outside of the reducer housing, which can be used to regularly check the reducer lubricating oil. Generally, the reducer lubricating oil covers half of the oil level mirror. If it is less than half of the oil level mirror, add oil.

The lubricating oil must be replaced after the reducer works for the first 400 hours. Check whether the lubricating oil needs to be replaced every six months. Mineral oil and synthetic oil must not be mixed.

Regularly add oil to the bearing parts. The bearing parts are easily damaged parts. Frequent refueling can extend the service life of the bearings.

Our company has advanced management and quality control systems and provides high-quality equipment with consistent quality. We have a professional team of engineers and provide thousands of successful cases and customized designs. "What do customers really need?" This question has always driven us forward.

For more information about shredders, please contact: info@utmach.com

CN

CN

EN

EN

TEL:+86-533-3588750

TEL:+86-533-3588750 FAX:+86-533-3588750

FAX:+86-533-3588750 MOBILE:+86-18653354363

MOBILE:+86-18653354363 E-MAIL:info@zbutm.com

E-MAIL:info@zbutm.com ADDRESS:No.145 Zhengtong Road,

ADDRESS:No.145 Zhengtong Road,