Waste plastic disposal? Explore the path to plastic recycling together

At present, the global production of plastics is still developing at a rapid pace, at the same time, the negative impact of plastics on the environment is also increasing. In order to solve the environmental problems caused by the development of plastics, many countries have proposed to reduce the amount (including saving raw materials and reducing the amount of waste plastic production) as the preferred strategy, to recycle, recycling as the focus, to degrade as a supplement to recycling and other principles and strategic measures, are promoting the coordinated development of plastics and the environment.

The recycling of old plastics has always been a topic of concern, which can turn industrial waste into valuable industrial production raw materials and realize resource recycling, which has great significance that cannot be ignored.

There are thousands of types of plastic products, each with its own composition and characteristics. Do you know what happens to the plastic waste you throw away? The main treatment methods of waste plastics at home and abroad are chemical raw material recycling, physical landfill, composite modification, combustion energy recovery and mechanical physical recovery.

(1) The recycling method of chemical raw materials is to decompose waste plastics into small molecules or oligomers by isolating air heating cracking, catalytic cracking or enzymatic decomposition and other methods to use as new chemical raw materials, the method is still in industrial research, not widely used, but it is also the most promising recycling method in the future. Waste plastic can also be directly catalytic cracked into fuel oil, and it can also be reused by breaking it down into small molecular compounds through plastic biodecomposition enzymes.

(2) The physical landfill method is to directly bury waste plastics in natural landfills below the surface, which is easy to cause secondary pollution to the environment.

(3) Composite modified utilization method is to use waste plastics through physical methods and asphalt or building materials after composite modification for road laying, or use as building materials.

(4) Combustion energy recovery method is the waste plastic through combustion to convert its heat into electricity or heat energy for metal smelting, the method has been widely used, if the combustion of the exhaust gas after harmless treatment, is also a very environmentally friendly recycling method. However, due to the limited oil resources in the world, the recycling of plastics is of great significance.

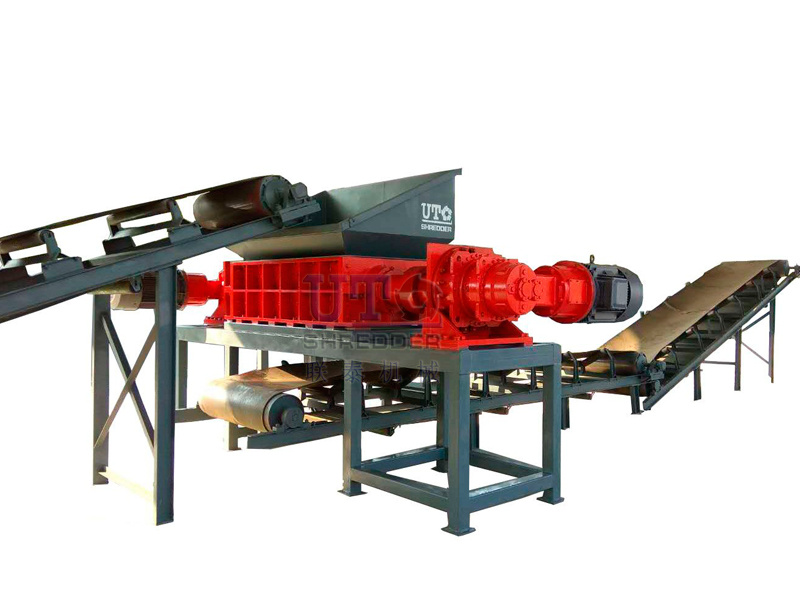

(5) Mechanical physical recovery method is to recycle waste plastics after crushing, cleaning, screening, classification, re-granulation and other processes to re-process and use, which can be used directly as raw materials or with new materials. Mechanical and physical recovery method is the main harmless industrial treatment method at present, and it is also the most friendly to the environment, and the most able to reduce the loss of oil and other resources.

To this end, at present, all countries in the world have invested a lot of manpower and material resources to develop a variety of key technologies for the recycling of waste plastics, and are committed to reducing the cost of plastic recycling and reuse to develop their appropriate application fields. Zibo Liantai Machinery Co., Ltd. is engaged in the recycling, recycling and utilization of renewable resources, and the company has innovated and opened up the whole industrial chain of plastic recycling and reuse.

In the future, we will focus on the advantages of the whole industrial chain of resource recycling and recycling, vertically expand the field of PE, PP and other varieties of plastic recycling, horizontally expand the field of multi-material resource utilization, driven by independent innovation, and continue to research and develop recycling and recycling technologies to contribute to the realization of sustainable development of the earth!

CN

CN

EN

EN

TEL:+86-533-3588750

TEL:+86-533-3588750 FAX:+86-533-3588750

FAX:+86-533-3588750 MOBILE:+86-18653354363

MOBILE:+86-18653354363 E-MAIL:info@zbutm.com

E-MAIL:info@zbutm.com ADDRESS:No.145 Zhengtong Road,

ADDRESS:No.145 Zhengtong Road,