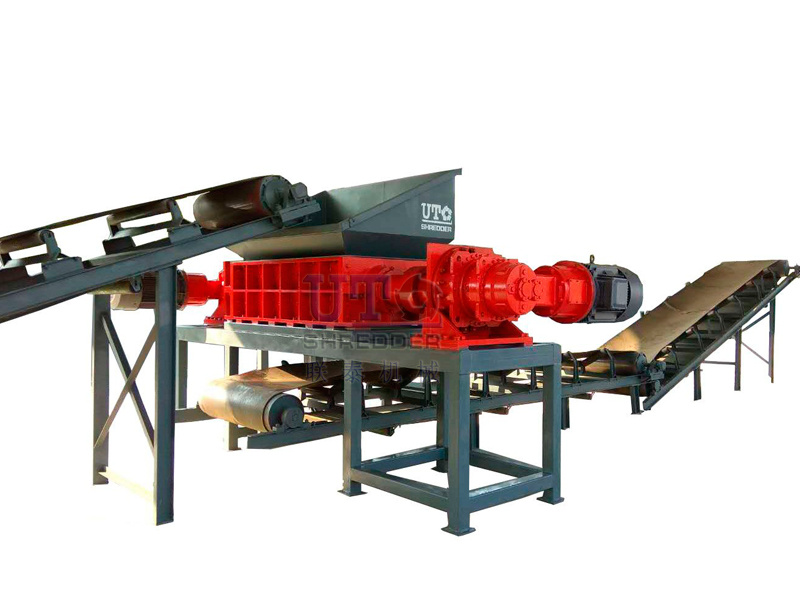

Does the tearing machine conform to the new quality productive forces?

Yes, the use of a shredding machine, such as a single shaft shredder, aligns with the principles of harnessing new quality productive forces. Here's how:

1. Efficiency and Automation: Shredding machines improve efficiency by automating the process of breaking down materials into smaller, more manageable pieces. This automation reduces the need for manual labor, thereby optimizing productivity.

2. Resource Optimization: By shredding materials, the machine facilitates the optimization of resources. It allows for the recycling and reuse of materials that might otherwise be discarded as waste, contributing to a more sustainable and resource-efficient production process.

3. Innovation and Technological Advancement: Shredding machines represent technological advancements in waste management and recycling. Their design and operation demonstrate innovation in utilizing machinery to transform waste into valuable resources, which is in line with the development of new quality productive forces.

4. Environmental Considerations: Utilizing shredding machines helps address environmental concerns associated with waste management. By reducing the volume of waste and enabling recycling, these machines contribute to environmental sustainability, which is a fundamental aspect of harnessing new quality productive forces.

5. Adaptability and Flexibility: Shredding machines are adaptable to various materials and applications. This flexibility allows industries to optimize their production processes by efficiently managing waste and resources, thus meeting the demands of changing markets and consumer preferences.

In summary, the use of shredding machines conforms to the principles of harnessing new quality productive forces by improving efficiency, optimizing resources, fostering innovation, addressing environmental concerns, and offering adaptability to changing needs and circumstances.

CN

CN

EN

EN

TEL:+86-533-3588750

TEL:+86-533-3588750 FAX:+86-533-3588750

FAX:+86-533-3588750 MOBILE:+86-18653354363

MOBILE:+86-18653354363 E-MAIL:info@zbutm.com

E-MAIL:info@zbutm.com ADDRESS:No.145 Zhengtong Road,

ADDRESS:No.145 Zhengtong Road,