Innovative solutions for waste plastic recycling and alternative fuel production

According to the China Material Recycling Association, in 2022, China's total plastic product output will be 63 million tons, of which 18.9 million tons will be recycled, accounting for 30%. The recycling capacity is obviously insufficient, and a large amount of waste plastics are not effectively utilized. Correspondingly, before the implementation of the "waste ban" in 2017, China imported millions of tons of waste plastics for industrial production every year. Even in 2017, there were still 5.83 million tons of imported waste plastics, indicating that China's demand for plastics is high. It can be seen that recycled plastics will undoubtedly face a long-term supply shortage, which can also be seen from the continued rise in PET plastic prices.

At the same time, with the approach of the "dual carbon" goal, the control of carbon emissions has been continuously strengthened, and carbon emissions and carbon emissions trading have also created a huge demand market for alternative fuels. Waste plastics can not only be recycled and reused as raw materials, but the raw materials after the shredder as a high calorific value fuel can naturally become a driving force for alternative fuels.

Waste plastics → Recycled raw materials

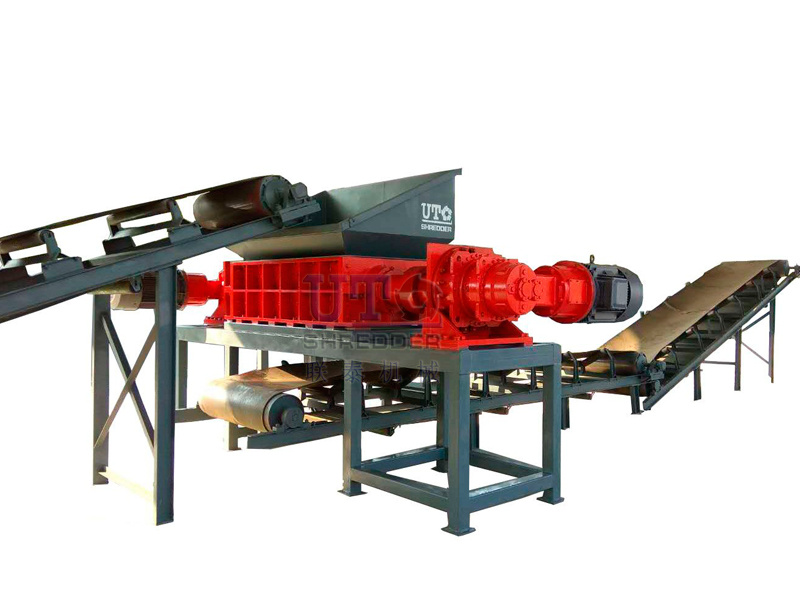

Plastic waste such as PP, PE, HDPE can be shredded by special plastic shredders, and magnetic separators can be used to automatically remove iron to obtain pure recycled raw materials and realize resource recycling. This process is simple and efficient, using pure mechanical physical shredding to maintain the original plastic quality during unloading, which is convenient for downstream direct processing into various plastic products.

Recycled raw materials → Production of alternative fuels

Shredders can not only help reduce the accumulation of waste plastics and reduce environmental pollution, but also convert waste plastics into reusable materials and promote the circular economy.

The shredded plastics can also be used in processes such as pyrolysis or gasification to convert into alternative fuels, further reducing dependence on fossil fuels.

From the release of the "Opinions on Accelerating the Construction of a Waste Resource Utilization System" by the General Office of the State Council in early February to the inclusion of the "Promoting the Development of Waste Resource Utilization Industry" in the government work report during the two sessions in March, it all shows that the government attaches great importance to the resource utilization of waste. As an important part of this system, waste plastics will have broad development prospects whether they are converted into recycled raw materials or used as alternative fuels. Let us wait and see!

CN

CN

EN

EN

TEL:+86-533-3588750

TEL:+86-533-3588750 FAX:+86-533-3588750

FAX:+86-533-3588750 MOBILE:+86-18653354363

MOBILE:+86-18653354363 E-MAIL:info@zbutm.com

E-MAIL:info@zbutm.com ADDRESS:No.145 Zhengtong Road,

ADDRESS:No.145 Zhengtong Road,