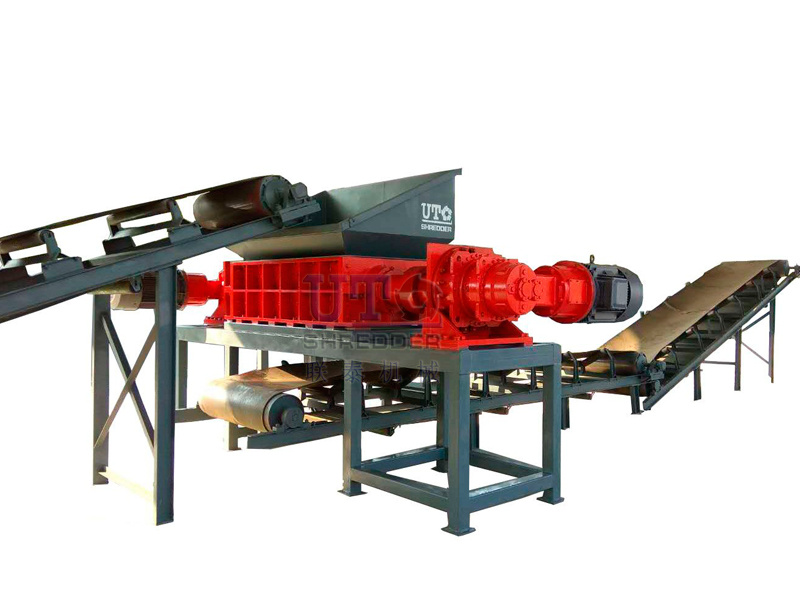

How to judge whether the shredder blade needs maintenance and replacement

The cutter is the most critical part of the shredder. The cutter of the shredder should be checked regularly to further protect the machine. How to judge whether the shredder blade needs grinding and maintenance

1. When the quality of shredder blade no longer meets the requirements;

2. When the energy consumption of the machine tool increases significantly;

3. When the edge of the cutting material has obvious cracks;

When we find that the tool is not so useful when working, or the shredder has changed significantly in discharging, or even can not meet the crushing requirements, it indicates that the tool life is up, and it needs to be maintained or even replaced with a new tool. Scientific adjustment of the rotating speed of the shredder cutter and proper maintenance and replacement can not only increase the output, but also avoid unnecessary wear of the cutter and prolong its service life.

Therefore, we must check in advance. Before the work is really affected, replace the tool that has been worn and cannot continue to work normally. Whether it is the life material, the continuous grinding will eventually wear out. During the daily operation of the twin shaft shredder, it is necessary to strengthen the maintenance and repair of the cutter. When the cutter has problems, it should be solved as soon as possible to determine when it must be stopped and repaired or replaced in time.

CN

CN

EN

EN

TEL:+86-533-3588750

TEL:+86-533-3588750 FAX:+86-533-3588750

FAX:+86-533-3588750 MOBILE:+86-18653354363

MOBILE:+86-18653354363 E-MAIL:info@zbutm.com

E-MAIL:info@zbutm.com ADDRESS:No.145 Zhengtong Road,

ADDRESS:No.145 Zhengtong Road,