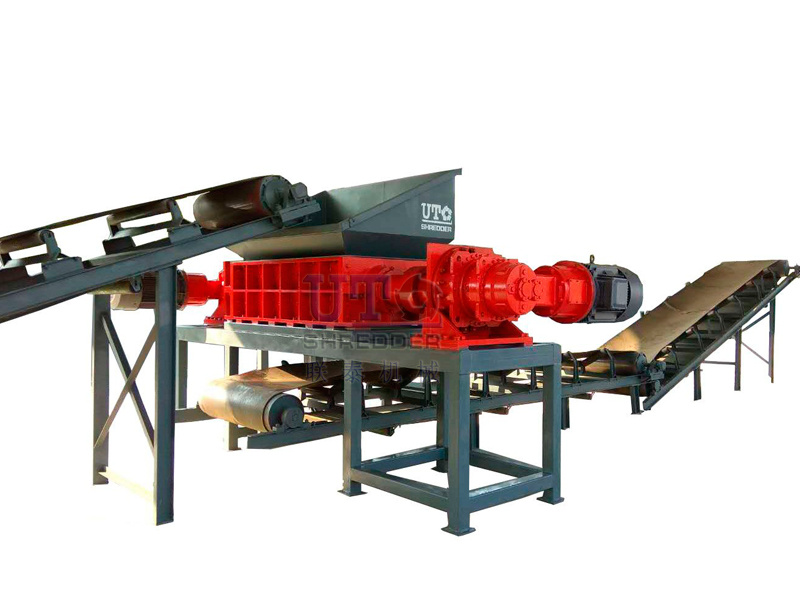

A brief introduction to the shredder

According to different material properties and shredding requirements, different types of shredders will be selected, such as single shaft shredder, double shaft shredder, primary shredder, and four shaft shredder. Each shredder has its own suitable application field. As a representative of high production capacity and small discharge size, single shaft shredder is well recognized by customers. This article will introduce the application range of single shaft shredder and how to achieve high capacity and small discharge size.

The main shaft of shredder uses the forged circle in the round steel as the raw material, which has higher density and higher strength. Yuangang has been quenched and tempered, forged and roughed to reach the standard shape. The finishing of the spindle is all integrally processed in its own machining center, and the tolerance of the shaft can be controlled within 10 wires (1mm is equal to 100 wires).

The structure design of the main shaft and cutter head of the shredder is perfected by our company's nearly ten years of on-site production experience. The cutter head structure is selected in a stepped spiral shape, which can make the load in the shredding process more uniform and ensure smooth operation.

Single shaft machine has a wide range of applications, whether it is flexible and high strength materials, or low density of light substances, it can run smoothly. Application include leather scraps, cloth scraps, municipal solid waste, paper mill waste, rubber scraps, branches, decoration templates, all kinds of plastic, film, biomass straw, corrugated cardboard, and so on.

If you have any shredding requirement or want to know more about single shaft shredder, please feel free to contact us and we are willing to help you.

CN

CN

EN

EN

TEL:+86-533-3588750

TEL:+86-533-3588750 FAX:+86-533-3588750

FAX:+86-533-3588750 MOBILE:+86-18653354363

MOBILE:+86-18653354363 E-MAIL:info@zbutm.com

E-MAIL:info@zbutm.com ADDRESS:No.145 Zhengtong Road,

ADDRESS:No.145 Zhengtong Road,