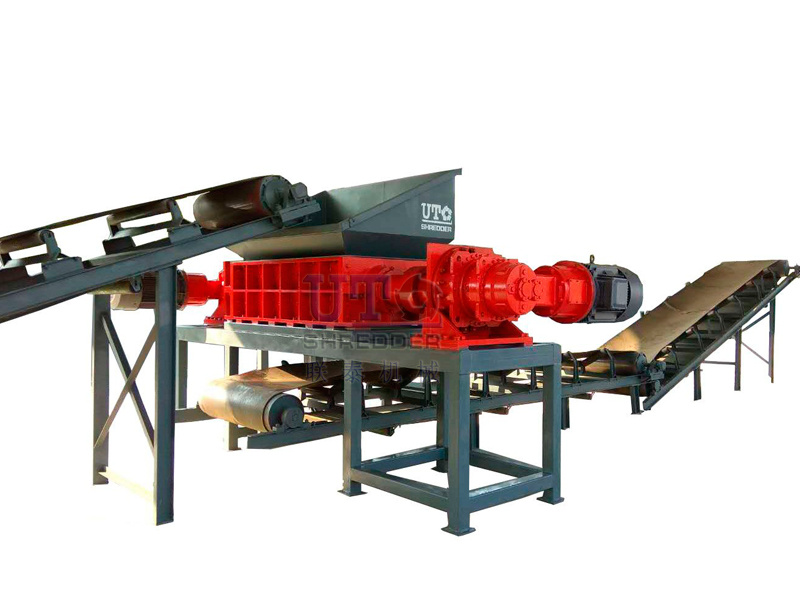

Dynamic Balance Test for our Granulator Machine

In modern industrial processes, the efficiency and reliability of disintegrators are critical to maintaining smooth operations and consistent product quality. Central to achieving precise disintegration is the balanced agitation of the drum.

Why Balanced Drum Agitation Matters:

1. Reduced Vibration and Noise: Unbalanced drum agitation can cause increased vibrations, compromising equipment stability and operator comfort.

2. Extended Equipment Lifespan: Balancing the drum minimizes uneven forces on bearings and seals, thereby reducing wear and extending the operational lifespan of the equipment.

3. Enhanced Operational Stability: Stable drum agitation ensures consistent performance, minimizing downtime and maximizing operational efficiency.

4. Quality Assurance: Balanced drum agitation guarantees uniform particle size during the disintegration process, ensuring consistent product quality.

Contact Us Today

Whether your disintegrator requires initial drum balancing or ongoing maintenance, our specialized services are geared towards enhancing operational efficiency and equipment reliability. Reach out to our experts today to discover how balanced drum agitation can elevate your disintegration processes! Contact us for more information: info@utmach.com.

CN

CN

EN

EN

TEL:+86-533-3588750

TEL:+86-533-3588750 FAX:+86-533-3588750

FAX:+86-533-3588750 MOBILE:+86-18653354363

MOBILE:+86-18653354363 E-MAIL:info@zbutm.com

E-MAIL:info@zbutm.com ADDRESS:No.145 Zhengtong Road,

ADDRESS:No.145 Zhengtong Road,