About plastic pelleting equipment

Waste Plastics, plastic barrels, plastic products are insoluble materials, if thrown directly to the landfill, it is difficult to decompose, cannot be decomposed and turned into dust, but will pollute the environment. The method of waste plastic recycling is to first waste plastic centralized acquisition to the waste station, and then by the purchase of plastic recycling products to do renewable resources. First concentrated crushing into small particles, re-granulation into raw materials, so not only reduce pollution, but also reduce costs. Plastic barrel chemical drum needs to be broken into small pieces can be granulated into renewable raw materials, which requires plastic granulator.

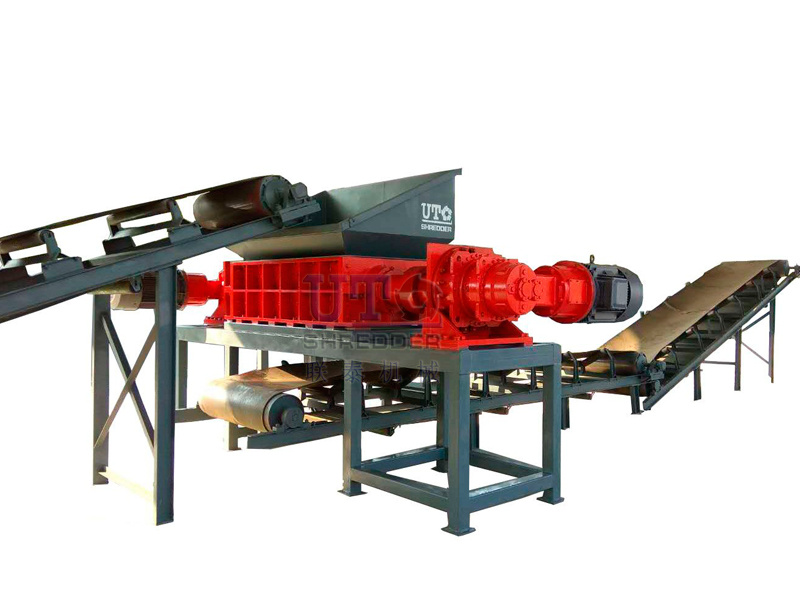

The G-series granulator of Zibo United Tech Machinery Co., Ltd. is a rubber and plastic recycling equipment designed to meet the production needs of high-volume crushing and one-time crushing of large-scale materials. It is mainly used for crushing plastics, rubber and light metals and other materials. As a high efficiency, low energy consumption, low noise waste recycling equipment, the pelletizer shell is made of solid welded steel structure, the appearance is exquisite, the box for the split, cleaning, changing knife, maintenance, the maintenance is very convenient. The cutter roller can choose the different cutter roller structure according to the broken material, and can be equipped with the pneumatic aggregate device and the sound insulation structure according to the customer demand. G series crusher include: Small Crusher, medium crusher, large crusher, powerful crusher and super crusher. The Crusher has the advantages of economy, practicality, simple operation and long service life.

Welcome to contact us for more detailed product information. We can recommend the selection of appropriate models, integrated to meet the production needs of the program. Allow customers to control the investment as far as possible, access to high cost-effective equipment products or production lines.

CN

CN

EN

EN

TEL:+86-533-3588750

TEL:+86-533-3588750 FAX:+86-533-3588750

FAX:+86-533-3588750 MOBILE:+86-18653354363

MOBILE:+86-18653354363 E-MAIL:info@zbutm.com

E-MAIL:info@zbutm.com ADDRESS:No.145 Zhengtong Road,

ADDRESS:No.145 Zhengtong Road,